Disruption is the only constant in a world with supply chains spanning continents, which relies on an infinite number of factors, including political stability, availability of raw materials, consumer demand, and even the weather.

The pandemic revealed this vulnerability: plants shut down, ports congested, and stores scurried to justify empty shelves. However, it is against this backdrop that one will say that a new power has emerged silently in the future of logistics and trade. It is not human intuition but the Invisible Hand of Artificial Intelligence (AI).

The global supply chain, once a fragile network, is now an intelligently orchestrated organism, guided by the Invisible Hand of AI.

Raising the Bar: A New Supply Chain DNA.

Supply chains have been responsive in the past. Issues were found only when they caused disruption: a late delivery here, a supplier going bankrupt there. Businesses used manual monitoring and inflexible forecasting models, which collapsed in the face of global shocks.

However, machine learning writes a new story. With access to real-time information on production lines, transportation hubs, and consumer behavior, AI systems not only identify all disruptions but also predict and recommend the most appropriate course of action. This dynamic DNA transforms supply chains, which are brittle and linear, into adaptive, bendable networks that do not break when bent.

The ability to see around the corner.

The first consequence of AI is a change in the kind of intelligence to prescriptive. To look ahead, AI models take in an enormous, unstructured flood of data, including satellite weather patterns, port congestion, trade tariffs, and social media sentiment.

Consider the case of a container ship held up in bad weather off Singapore.

-

Traditional systems would register the delay only after it cascaded down the line.

-

AI systems analyze vessel telemetry and satellite data to predict the delay hours before it happens. They can then automatically prescribe actions: rerouting shipments, adjusting inventory levels in local hubs, and calculating the most cost-effective alternative transport, all before customers even notice the original hiccup.

AI algorithms analyze vast datasets to “see around the corner,” transforming reactive logistics into prescriptive action that anticipates disruptions before they materialize.

Self-Healing Processes: The Immune System of Commerce.

Physiologically, the human body does not wait until it becomes crippled by a disease; it responds by dispatching antibodies right away.

Supply chains are receiving an AI akin to an immune system, where self-healing can be implemented and done in machine time.

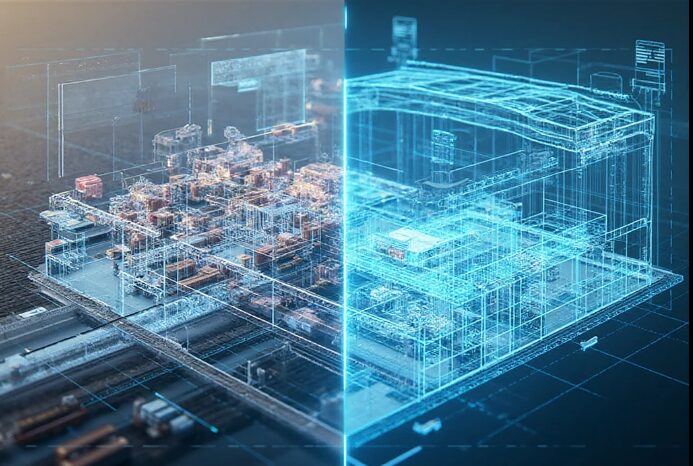

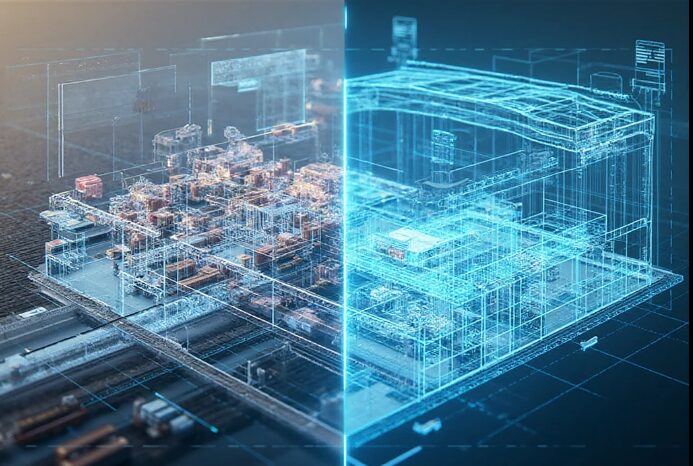

The Digital Twin creates a live, virtual replica of the supply chain, enabling AI to simulate complex disruptions and engineer resilience by design.

Making Systems Digital with the Digital Twin.

The final barrier to the unknown is the Digital Twin—an ideal, live-streaming, virtual representation of the whole physical supply chain.

The AI exposes this twin to disastrous virtual events: it simulates a congestion of a canal or an abrupt 50% spike in demand.

This simulation will take place in milliseconds, enabling the AI to compute and pre-plan an ongoing, updating contingency playbook that is capable of executing in real-time.

Resilience=AIPredictive Power×Digital TwinSimulation Speed

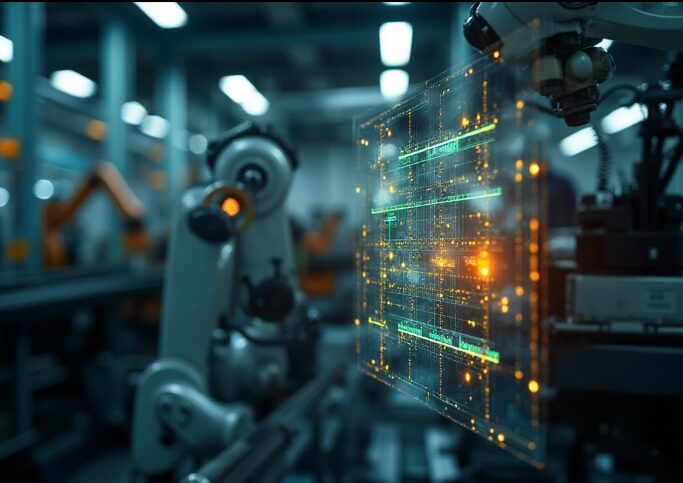

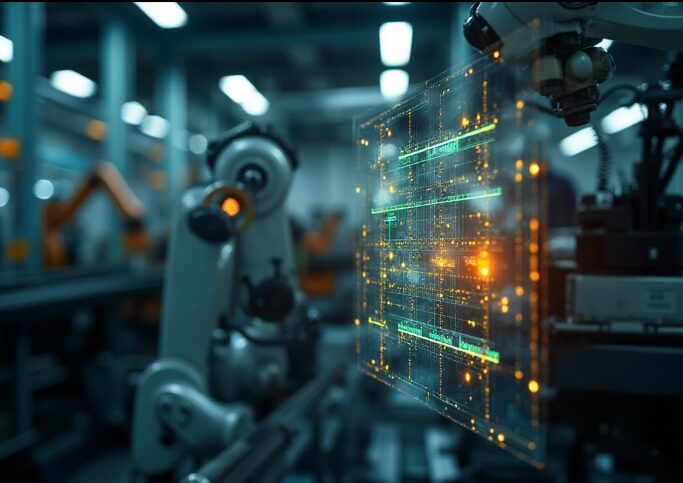

Zero Downtime: Predictive Maintenance.

This self-healing applies to the machines as well. Predictive Maintenance (PdM) with AI will track the acoustic, thermal, and vibrational characteristics of each motor and robotic arm.

It picks up micro-signatures of degradation and a small, invisible increase in temperature and gives an alarm a few days or weeks before a part breaks down.

This active scheduling basically eradicates planned outages, so the complete circuit becomes self-corrected and never leaves a trace of downtime.

Predictive Maintenance utilizes AI to detect micro-signatures of degradation in machinery, preventing costly unplanned downtime and ensuring the supply chain’s continuous operation.

Beyond Efficiency: Creating End-to-End Resilience.

Efficiency has always been the Holy Grail of supply chains: to spend less and to move faster. Efficiency does not ensure survival. AI shifts the goalpost to resilience, which means being able to withstand shocks without crumbling.

This is the real strength of AI, which helps to sort out the noise in the ocean of data created by the IoT sensors, blockchain records, and old ERP systems. This capability to convert noise into signal not only allows real-time orchestration to align production plans, global logistics, and last-mile delivery but was previously in the realm of science fiction. AI not only maximizes supply chain activity, but it also changes the definition of supply chains.

The Strategic Human, The Future Playbook.

Further into this decade, AI will transform into a hidden composer, something that becomes more visible only when things go well but that is so needed when things go wrong. It is not a human-less network that will become the future of commerce, but a high-stakes partnership.

Artificial Intelligence automates the repetitive, tactical decisions, allowing human expertise to concentrate on strategic management and ethical governance. The best companies will be those whose supply chain adapts like the organism—resilient, self-healing, and directed by the silent and strategic intelligence of machine learning

General News6 days ago

General News6 days ago

General News2 days ago

General News2 days ago

Politics2 days ago

Politics2 days ago

General News2 hours ago

General News2 hours ago